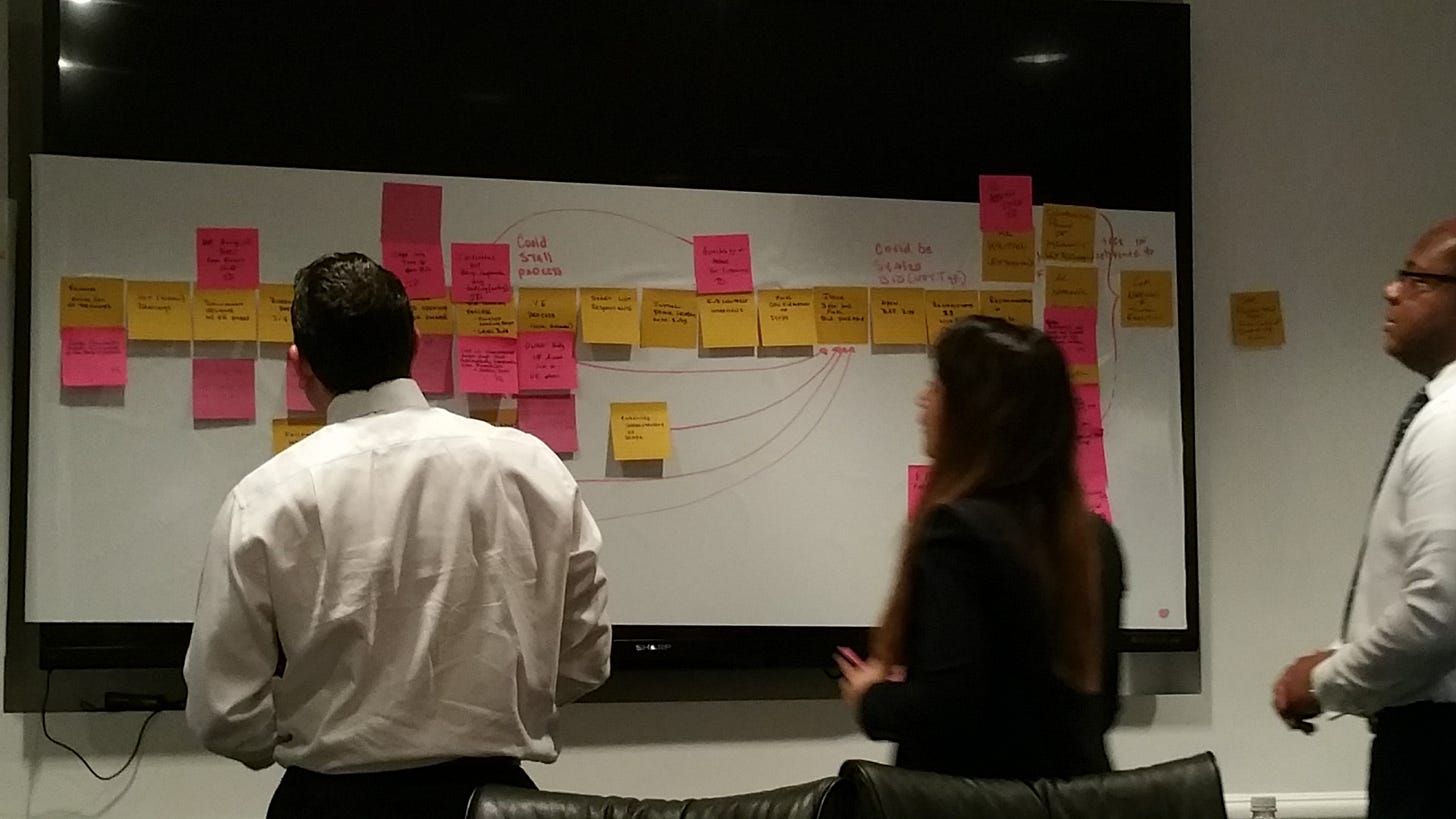

John Shook and I were standing in a factory. He breathed in deeply and smiled and sighed, “You know, I just love factories.” He looked so at home, at peace. He was in his element in the factory we were in. The feel of it. The sound. The energy. The flow. The mistakes. Dude just loves factories. When Toni and I are doing our Modus-style value stream mapping workshops, this is kind of how I feel.

It can be in person or on-line, but there's something intoxicating about watching professionals dig deep into what they actually do every day. Hearing them wrestle with how their work really happens. How they realize the sanitized version they believe in is a more messy, complicated, and human reality.

Like John likes to see the flow of goods, the creation of value, and the ways he can help streamline. I watch the flow of conversation, relationships, ideas, and the creation of value. I watch the people on the team discover who they really work with, how they work together, and where the work flows or gets stuck. It's can be (often is) raw and uncomfortable when we start. These aren’t systems people are used to seeing.

Most teams run not on process, but on assumptions and hope. While we go through the exercise, people realize they don't work the way they thought they did. They see where they're unwittingly creating problems for each other. They confront the gaps between what they say they value and what their actual process rewards. They are seeing their relationships and the customer journey and the workflow at the same time. In context.

And they care. So they start negotiating. Not the adversarial kind where someone wins and someone loses, but the collaborative kind where everyone's trying to figure out what's important to each other. They build a "shared professionalism", they create a mutual understanding of what good work looks like and what each person needs to do that good work. Then they start to create expectations to do those things.

Individuals Work In Teams to Create Value

This creates a game where the goal is to stop being collections of individuals with competing priorities and start becoming genuine collaborators. To become an actual team. Seeing the work lets them vent frustrations they've been nursing, see them in how work is done, and realize these issues aren’t some blamable personal failings but systemic issues the team can fix together. The energy in the room shifts from defensive to creative.

And at this point, the team starts to optimize. They organize. They focus.

The energy and flow John loves about factories comes from people understanding their place in a larger system that creates real value. The work in a factory is very visual, things are moving from collections of parts to shippable wholes. In knowledge work, we don't have the luxury of seeing our "factory floor." Most of our value creation happens in our heads and in our handoffs to each other.

For the factory, you can go-see locations of issues to improve or optimize. For the rest of us, we need a way to see the work. The value stream map becomes that place to go see. In Lean parlance, the VSM becomes the beginning of a visual Gemba.

Building a Team Together

The exercise starts with an end-state (what value are you delivering?). When professionals map their work backwards from the end state, they're forced to slow down and examine each step. They need to be thoughtful about what happens. They can't rely on the convenient narratives they've constructed. They have to confront what actually happens.

The teams always surprise me and themselves. Always. The person who thought they were being helpful realizes they're creating a bottleneck. The team that prided itself on quality discovers they create defects through their handoff process. The process everyone assumed was working fine turns out to be held together by hidden heroic individual efforts that aren't sustainable.

Rather than focusing on failure or assigning blame (holding people accountable), we are creating the conditions where professionals can act with confidence because they finally understand the system they're part of (being responsible). When people can see how their work connects to others' work, when they understand what success looks like from their teammates' perspectives, they can make better decisions in real time.

That shared professionalism emerges from honestly examining how value gets created and figuring out together how to make it better. It's professionals respecting each other enough to tell the truth about what's working and what isn't.

John's right about factories. There is something beautiful about watching people create value together with clarity, purpose, and mutual respect. We just have to see our own version of that factory. We need to see how we work together to get things done.